Waterproof aviation connector cable plugs are specialized electrical connectors designed to ensure reliable performance in harsh environmental conditions, particularly in the aviation industry.

Our Blog

Recourses, News, and Tutorials

Latest Articles

Energy Storage Connector for Energy Storage System

The IP67 High Voltage Energy Storage Connector is a crucial component in energy storage systems, providing a reliable and safe connection for high voltage applications.

Important Purpose Of The Plant Growth Light Connector

The purpose of a plant growth light connector is to provide a reliable and efficient connection between the plant growth light and the power source.

Junction Boxes Approved Up To IP68 Provide A High Level Of Protection Against Water And Dust

When it comes to electrical connections, ensuring that they are both protected and compact is essential for maximum versatility. This is where waterproof junction boxes come into play.

Circular Waterproof Connectors are Designed to Provide Secure and Reliable Connections in Harsh Environments

Circular Waterproof Connectors are designed to provide secure and reliable connections in harsh environments where water and other contaminants may be present.

Device and Cable Connectors for Energy Storage Systems

Connectors play a crucial role in energy storage systems by providing a secure and reliable connection between various components.

What Are Industrial Connectors?

Industrial connectors are devices used to join electrical circuits in industrial settings. They are designed to provide a secure and reliable connection between different components, such as cables, sensors, and machines.

Popularization Of Some Product Knowledge About Waterproof Connectors

Waterproof connectors are specialized electrical connectors that are designed to prevent the ingress of water and other liquids.

Which PV Connector Is Positive?

In the world of photovoltaic (PV) connectors, it is important to understand which connector is positive and which is negative in order to properly connect solar panels and ensure optimal performance.

Comprehensive analysis of waterproof connector technology: allowing electronic equipment to operate safely in extreme environments

Comprehensive analysis of waterproof connector technology, in-depth discussion of its applications in different fields, and how to select, use and maintain waterproof connectors.

Mastering the Art of Waterproofing: Tips and Techniques for Reliable Electrical Connectors in Wet Environments

Electrical connectors play a vital role in electrical and electronic systems, facilitating the connection and disconnection of wires and cables. However, when these components are exposed to moisture or water, it becomes imperative to implement proper protection measures to prevent damage or failure.

What is the installation method of the waterproof connector?

The installation of waterproof connectors is mainly divided into welding and crimping methods. Each installation method has its own characteristics. With the different application conditions, the installation methods we use are also different.

What is the important role of waterproof connectors in the field of outdoor lighting?

waterproof connectors are essential in the field of outdoor lighting. They provide a safe and reliable connection between two electrical components, while protecting against moisture and other environmental elements.

What is the selection method of waterproof connector?

Generally speaking, there are a series of numbers on the description of the waterproof connector. The larger the number, the stronger the waterproof ability of the joint. This is a reference for everyone when purchasing waterproof connectors.

The waterproof principle and working mechanism of waterproof connectors

This article will provide an in-depth introduction to the waterproofing principle and working mechanism of waterproof connectors, and reveal the secrets of this technology to readers.

Waterproof connector: a key tool to ensure device safety

In modern society, electronic equipment is used increasingly widely, and these equipment often need to work in various harsh environments, such as moisture, rain, dust, oil, etc. Therefore, waterproof connectors have become an indispensable part of modern electronic equipment.

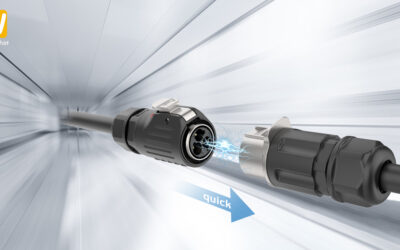

How to Install A Screw Waterproof Connector?

Quick, Easy to install, and Compact. Using the fewest number of components, we ensure that the products are installed in an easy way and in the least possible time.

General knowledge of connectors

The connector is in more frequent contact with electrical engineers and component technicians. It is blocking in the circuit or circuit isolation, bridging communication, so that the current circuit to achieve the desired function, is an essential part of electronic devices.

About the Product Types of Electrical Connectors

Due to the presence of a large number of electrical equipment in the electrical and electronics industry, the number of electrical connector variants is equally huge. Connector types include terminals and wire nuts, terminal posts, terminal blocks, crimp terminals, insulation displacement connectors, plug and socket connectors, etc.

What are the advantages of circular connectors? You don’t always know!

Circular connectors are made up of contacts, insulators, housings, locking mechanisms, and accessories to provide power, signal, and data connections for various devices and systems. They are widely used in multiple industries and applications such as new energy, industrial manufacturing, and the Internet of Things.

What Does A Waterproof Connector Housing Do?

good shell is not only a good visual aesthetic and tactile, but more importantly, it is one of the very key physical structures of the connector, which assumes a very important role.

What is the corrosion of waterproof connector plugs?

Object oxidation is a relatively common phenomenon, in fact, waterproof connector plugs are also oxidized a large part of the reason is the failure to use corrosion occurs, we are here today to learn more about the various types of corrosion-resistant waterproof connector plugs!

Where are the basic advantages of ip68 connector design?

The traditional connector is not waterproof, but after the improvement of waterproof technology, then the new era of waterproof ip68...

What is the manufacturing process of waterproof wire connectors?

Waterproof wire connectors are increasingly widely used, many people read my previous post, should know the advantages and uses of...

Do you know why the industrial connector contacts must be plated with a layer of protective metal?

We all know that the contact is a key structural component of the industrial connector, the main component is a copper alloy, the outer layer of a protective metal plating, then the contact parts why the choice of copper alloy and the need to do the plating process?

Basic properties, structure and types of electric connectors

For the many types and varieties of electric connectors, how to choose the right electric connector issues, this article briefly describes the three basic properties of electric connectors, structure and classification, so that we have a basic understanding of the connector.

Do you know the male female connectors plug force four points of attention?

99% of people do not know the male female connector plugging force of the four big pits, plugging force is a key indicator of the male female connector, directly related to the performance and use of the connector, and the impact of the connector plugging force of the four main factors.

What factors affect the insulation performance of plastic waterproof connectors?

Plastic waterproof connector is an electronic component used to achieve signal and current power transmission and control. Which insulator is an important part of the plastic waterproof connector, its insulation performance is directly related to the normal use of the plastic waterproof connector and safety.

Do you know what kinds of fire rating UL94?

Flammability UL94 rating is the most widely used standard for the flammability performance of plastic materials. It is used to evaluate the ability of a material to extinguish after being ignited. There are a variety of ways to judge it based on burn rate, burn time, drip resistance, and whether the drip beads burn.

Cable Connector Waterproof Test Standard Procedures

Three samples of each thickness are to be tested. Prior to the test, the waterproof cable connector samples are to be placed at 20°C and 50% RH for 48 hours. The cable connector samples should be placed parallel to the long axis and at an angle of 45・ to the short axis.

Popular videos

Waterproof Aviation Connector Cable Plugs Are Specialized Electrical Connectors

Waterproof aviation connector cable plugs are specialized electrical connectors designed to ensure reliable performance in harsh environmental conditions, particularly in the aviation industry.

Energy Storage Connector for Energy Storage System

The IP67 High Voltage Energy Storage Connector is a crucial component in energy storage systems, providing a reliable and safe connection for high voltage applications.

Important Purpose Of The Plant Growth Light Connector

The purpose of a plant growth light connector is to provide a reliable and efficient connection between the plant growth light and the power source.

Junction Boxes Approved Up To IP68 Provide A High Level Of Protection Against Water And Dust

When it comes to electrical connections, ensuring that they are both protected and compact is essential for maximum versatility. This is where waterproof junction boxes come into play.

Circular Waterproof Connectors are Designed to Provide Secure and Reliable Connections in Harsh Environments

Circular Waterproof Connectors are designed to provide secure and reliable connections in harsh environments where water and other contaminants may be present.

Device and Cable Connectors for Energy Storage Systems

Connectors play a crucial role in energy storage systems by providing a secure and reliable connection between various components.

1-400x250.jpg)