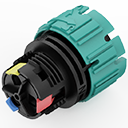

Waterproof connector is a device used to fix the connection between cables and pipes. It is mainly used in outdoor products, automobiles, industrial automation, instrumentation and other fields. It is waterproof, dustproof, vibration-resistant, and corrosion-resistant, and can ensure the reliability and stability of the connection in harsh environments. There are many types of waterproof connectors, including plug type, socket type, stud type, flange type, etc. Different types of waterproof connectors are suitable for different application scenarios.

What is the selection method of waterproof connector?

What is the function and necessity of the cable waterproof connector?

What is the difference between indoor and outdoor waterproof connectors?

What is the selection method of waterproof connector?

1. Generally speaking, there are a series of numbers on the description of the waterproof connector. The larger the number, the stronger the waterproof ability of the joint. This is a reference for everyone when purchasing waterproof connectors. This number is a two-digit number, representing different parameters of the waterproof connector. The first digit is from 0 to 6, representing the waterproof connector’s ability to protect against solids. The larger the value, the stronger the protection ability. If it is 0, it means no protection at all.

2. The second digit indicates the water protection ability, and this value is from 0 to 8. Like the ability to prevent solids, the larger the value of the second digit, the more proportional the change in the protection ability. 0 means that there is no waterproof ability at all, which is the same as non-waterproof products. If you want to buy waterproof products, the value behind is 0, so you don’t need to buy them. On the contrary, if it is the largest value, 8, it means that the waterproof ability is very strong, and it can be used underwater for a certain period of time without any problem.

What is the function and necessity of the cable waterproof connector?

Prevent moisture from intruding into the insulation layer of the motor to cause leakage, and also play a role in anti-corrosion. Since the motor will generate a certain amount of heat during operation, it is necessary to effectively dissipate heat from the cooling system of the motor.

The protective cover of the motor casing is one of the important parts of the heat dissipation of the motor. If the motor does not take corresponding protective measures, it will cause corrosion of internal parts, and in severe cases, it will cause faults such as short circuits.

What is the difference between indoor and outdoor waterproof connectors?

The outdoor waterproof connector is made of waterproof treatment, and the waterproof junction box with glue filling has a protection level of IP6, which can be used directly underwater, and has a wide range of applications. Choose a dedicated cable waterproof connector. Although the cable waterproof connector has a waterproof function, the main function of the cable waterproof connector is to seal the cable. In order to prevent leakage, the underground cable connection should be treated twice, that is, tightly wrapped with insulating black cloth, and then wrapped with waterproof plastic cloth.

Easy, safe, maintenance-free: Perfect for outdoor lighting, Machines, and Equipment or Communication equipment or as pluggable connectors in cable ducts or control cabinets – E-Weichat offers the right electrical interconnect solutions for every application.

9.jpg)

0 Comments