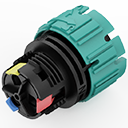

Key Features of Circular Waterproof Connector

1. Waterproof Design: The circular waterproof connector is equipped with a robust waterproof design that ensures protection against moisture, dust, and other environmental elements. This feature allows the connector to perform reliably in harsh conditions and outdoor environments.

2. Durable Construction: The connector is built with high-quality materials that enhance its durability and longevity. This ensures that the connector can withstand constant use and exposure to various environmental factors without experiencing mechanical failures or performance issues.

3. Secure Connection: The circular waterproof connector is designed to provide a secure and stable connection between the connected devices. This feature helps prevent accidental disconnections or interruptions, ensuring consistent and uninterrupted power and signal transmission.

4. Easy to Install: The connector is designed for easy and hassle-free installation, making it suitable for both professional and DIY applications. The user-friendly design allows for quick and efficient setup, saving time and effort during installation and maintenance processes.

5.Versatile Compatibility: The circular waterproof connector is designed to be compatible with a wide range of devices and equipment, making it a versatile solution for various applications. This feature allows for seamless integration with different types of devices, enhancing flexibility and convenience in connectivity solutions.

Circular Waterproof Connectors are designed to provide secure and reliable connections in harsh environments where water and other contaminants may be present. These connectors are commonly used in marine industry for connecting various electronic components on boats and ships. They are also widely used in outdoor lighting applications, ensuring that the electrical connections remain safe and functional in all weather conditions. In addition, circular waterproof connectors are frequently seen in industrial equipment where reliability and durability are crucial for smooth operation of machinery. With their easy installation process, these connectors offer a convenient solution for connecting electrical components in a variety of applications.

In the design of circular waterproof connectors, important considerations include the choice of materials, sealing technology, and durability.

Materials: Circular waterproof connectors are typically made from high-quality materials such as stainless steel, aluminum, or plastic. These materials are chosen for their durability and resistance to corrosion.

Sealing Technology: The sealing technology used in circular waterproof connectors is crucial for maintaining a watertight seal and protecting the internal components from moisture and environmental contaminants. This may include features such as O-ring seals or potting compounds.

Durability: Circular waterproof connectors are designed to withstand harsh environmental conditions, including exposure to water, dust, and extreme temperatures. They are often tested for durability and reliability to ensure they can maintain a secure connection in demanding applications.

Circular waterproof connectors are typically made of high-quality materials that provide excellent resistance to water, dust, and other environmental factors. Commonly used materials for these connectors include stainless steel, aluminum, brass, and plastic. These materials are chosen for their durability, corrosion resistance, and ability to withstand extreme temperatures and harsh conditions.

Stainless steel is a popular choice for circular waterproof connectors due to its high strength, corrosion resistance, and long-term reliability. Aluminum is another commonly used material known for its lightweight design and resistance to wear and tear. Brass is often selected for its superior conductivity and resistance to corrosion, making it ideal for electrical connections. Plastic connectors are also available for applications that require a lightweight and cost-effective solution.

The sealing technology typically includes specialized seals and gaskets that create a watertight and dustproof barrier around the connector. These seals are made from high-quality materials that are resistant to degradation from water, oil, and other contaminants. Additionally, the design of the seals and gaskets is carefully engineered to provide a secure fit and prevent any gaps or leaks that could compromise the connector’s waterproofing capabilities.

The circular waterproof connector comes in various sizes to accommodate different requirements in terms of space and power. Common sizes include 9mm, 12mm, 16mm, and 21mm, with the option for custom sizes available as well. The size of the connector is important as it determines the amount of power that can be transferred through it, as well as the fitting and compatibility with other components. It is crucial to select the right size of the circular waterproof connector to ensure proper functionality and performance in the desired application. The size of the connector also plays a role in the overall design and aesthetics of the product, making it a key factor to consider during the selection process.

Voltage Rating:

The voltage rating of a circular waterproof connector is a crucial specification that determines the maximum voltage that the connector can safely withstand. This is important in ensuring the safety and performance of the connected equipment or devices.

Circular waterproof connectors typically have a voltage rating ranging from 250V to 600V, depending on the specific model and application requirements. It is important to carefully select a connector with the appropriate voltage rating to prevent electrical failures or hazards.

When choosing a circular waterproof connector, it is essential to consider the voltage requirements of the application to ensure compatibility and optimal performance. Additionally, it is recommended to consult the manufacturer’s specifications and guidelines to select the right connector with the suitable voltage rating for your specific needs.

9.jpg)

0 Comments