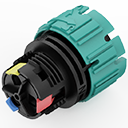

Electrical waterproof connector’s biggest advantage is to have good waterproof performance characteristics, to be able to electrical waterproof connector’s great advantage is, of course, in the waterproof characteristics to prevent the entry of water and erosion, and to prevent dust from entering the connector resulting in a decline in its performance, electrical waterproof connector can ensure that the electrical performance in use is not affected by external factors to ensure that the internal mechanical equipment is not damaged. The use of a good shell also ensures the stability of the electrical performance, but also has a high temperature resistance, resistance to pressure characteristics.

The following three types of electrical waterproof connectors are introduced respectively.

According to the structure type distinction or functional distinction: wire-to-wire electrical waterproof connectors, wire-to-board electrical waterproof connectors, board-to-board electrical waterproof connectors.

1. Wire-to-wire electrical waterproof connectors.

Wire-to-wire connection also includes a wire-to-cable or cable-to-cable form, the defining characteristic of the two single wire individuals or two cables should be connected in the long run to each other. Wiring method to two cable line butt terminals and then electrical waterproof connectors lock the wiring terminals to do waterproof, mainly for outdoor cable communication and power interconnection waterproof processing, IDC because of its superiority in relation to the wire and harness end processing and commonly used to dominate the cable electrical waterproof connectors, wire-to-wire electrical waterproof connectors have a variety of geometric plastic support parts such as right angle and round polymeric shape of the plastic parts. Most of the cylindrical type is the main, round type design better to wear and pressure resistance, etc., can be buried in water or ground.

2. Wire or cable to board electrical waterproof connectors.

Line to board electrical waterproof connector, half of the electrical waterproof connector is connected to the line or cable, there are also connected to the printed circuit board, the same as the aforementioned line connection, board connection is also the same, except that the need to press into or weld two pieces of connectors, its use is the electrical and electronic equipment shell cable line openings into the line to do waterproof processing, its terminals with the interface suitable for separable connectivity, and line to line electrical waterproof connector is much the same. Functionally the same product use is not the same

3. Board-to-board electrical waterproof connectors.

The first kind of board-to-board electrical waterproof connector set on the edge of the board so called card edge, its development to the end will become a two-piece electrical waterproof connector, because the technical performance of the printed circuit board and its size is growing, when the size of the board increases, the result will lead to electrical waterproof connector capacity becomes larger, thus increasing the number of terminals, electrical waterproof connector pull force becomes larger, the capacity of the printed circuit board will lead to excessive line density, a single piece electrical waterproof connector is difficult to meet its requirements, so the end of its development will be a two-piece electrical waterproof connector. Board-to-board applications in the more sophisticated products and equipment, board-to-board features are smaller in size and more widely used.

What is the difference between ordinary electrical waterproof connectors and aviation plugs, aviation plugs are connectors, aviation plugs are electromechanical components connected to the electrical circuit, the specification parameters required than the standard of ordinary connectors are much higher, so there is no classification with them, so its own electrical parameters are the first thing to consider when choosing an aviation plug.

9.jpg)

0 Comments